Module features

Strategies

The following machining strategies are available for tangent plane machining:

(1) Machining the face

(2) Machining the face with limit

(3) Machining the limit

Indexed machining

The face is machined with different orientations in specific areas. A high level of surface quality between the orientations is achieved thanks to a defined overlap.

Simultaneous machining

The entire face undergoes 5-axis simultaneous machining.

5-axis simultaneous machining is especially effective with dynamic machines.

.jpg)

Bottom machining

Bottom surfaces with undercut situations and edge areas of high walls or pocket bottoms can be optimally machined using the strategy for conical barrel cutters.

Automatic collision avoidance

In collision areas, the tool tilts upwards away from the contact point or guiding angle.

Barrel cutters in general

Barrel-shaped tools use a section of the circumference, allowing for very large radii. For example, the compact design of the tools allows for a cutting radius of 500 mm. Types:

-

General barrel cutter

-

Tangential barrel cutter

-

Conical barrel cutter

Conical barrel cutter

The conical barrel cutter represents a completely new type of milling tool geometry that was developed by OPEN MIND. Thanks to this innovation, faces with minimal curvature can be efficiently machined.

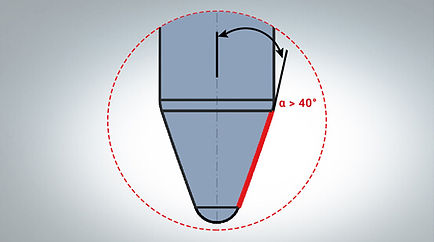

Conical angle greater than 50° for hub finishing

Conical angle of less than 40° for machining steep areas